Bill of Materials

The product structure provides a hierarchical classification of the items which form a product. With the product structure, the understanding of the components which compose a product as well as their attributes, can be represented. The product structure shows the material, component parts subassemblies and other items in a hierarchical structure that represents the grouping of items on an assembly drawing or the grouping of items that come together at a stage in the manufacturing process.

In the very early phases of new product design, engineers begin the design by sketching out a structure for the product which identifies the major components and systems that will combine to create the desired product. For each component, existing standard parts and previously designed custom parts must be evaluated for their ability to provide the necessary function. In those cases for which no existing alternative can be identified, the engineer must specify that new parts should be created, and the details of the structure begin to emerge. Product structure management provides the mechanism to capture and manage as-designed product structures with ease. It allows for the creation and re-use of unlimited numbers of parts and assemblies, to provide for many different variations of a basic structure or the creation of complex, one-of-a-kind structures.

Later in the development cycle, engineering parts lists or drawing parts lists are used to create a version of the product structure to support manufacturing. This standalone product structure is called the bill of materials.

Bill of Materials

A bill of material is a formally structured list for an object (semi-finished or finished product) which lists all the component parts of the object with the name, reference number, quantity, and unit of measure of each component. A bill of material can only refer to a quantity greater than or equal to one of an object. It is a product data structure, which captures the end products, its assemblies, their quantities and relationships.

There are usually two kinds of bills of materials needed for a product: engineering and manufacturing BOM. The engineering BOM normally lists items according to their relationships with parent product as represented on assembly drawings. But this may not be sufficient to show the grouping of parts at each stage of the production process nor include all of the data needed to support manufacturing or procurement. These requirements may force the arrangement of the product structure to be different in order to assure manufacturability. Thus, engineering and manufacturing will usually have different valid views for the same product.

Summarized Bill of materials

Summarized Bill of materials contains a bill of materials for Product 1 in which the total usage of each item is collected into a single list for the product. This kind of list is convenient for the master production schedule but results in the duplication assemblies. This implies that each product bill that uses assembly must be changed whenever there is a change in assembly. Furthermore, since lead times of intermediate assemblies cannot be determined, parts are ordered too early the first time they are encountered in the product structure.

Indented bill of materials

Other arrangements used in arranging the bill of materials is by indenting the product data as shown in Figure. One disadvantage of this method is that all components of an assembly are repeated each time the assembly is used, resulting in massive duplication of data.

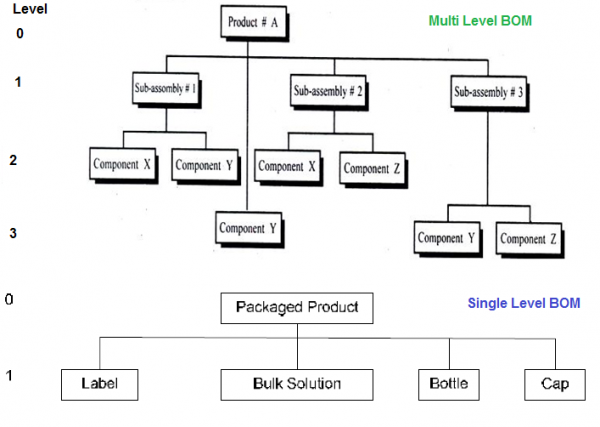

Single Level Bill Of Material

Maintains a unique end item for each possible configuration. This BOM structure is appropriate for MTS where the MPS is stated in end items. For each end item a single level bill is maintained which contains those components that physically go into the item. The single level BOM is consists of:

· Parent Item no.

· Component Item no.

· The qty needed to make a single parent item.

· The date on which this bill became active.

· The date on which this bill became inactive.

· The operation sequence number where this material is used.

Multi Level Bill of Material

A multi level BOM can be expanded as necessary to adequately describe a product that has subassemblies. When this is done it takes on a multi level tree structure. The tree has several levels. Each part or assembly has given a unique no. It is composed of the building blocks of single level product trees & each subassembly has it’s own BOM, but this has to be defined once & when it is defined it can be used by any other product that requires the same subassembly. The way that a product is defined is a key input to the master schedule.

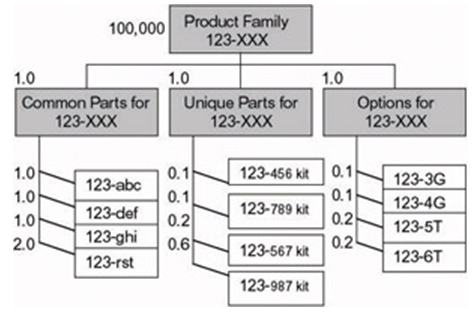

Planning BOM

It is an artificial grouping of items or events in BOM format used to facilitate master scheduling & material planning. Planning bills are a huge asset to good master schedulers. These planning shortcuts make it easier for master schedulers to maintain the plans without thousands of SKU-level forecasted orders to manipulate. If, for example, in January the forecasted plan for the month of July has 100,000 units and planning bills are used, the requirements driving the material requirements planning (MRP) plan would consist of one BOM (the planning bill) with a quantity of 100,000. The planning bill would take the expected mix and ratio it.

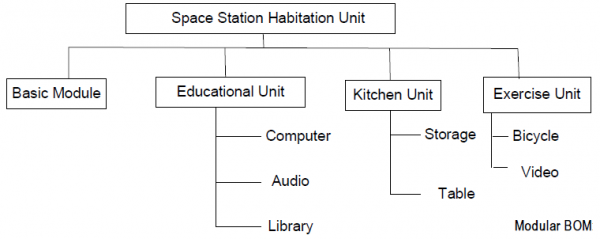

Modular BOM

Subassemblies - links components parts to options. When the combinations of end-item product are many, it is better to use the MPS at the option or module level. The MPS is stated in the terms in which the product is sold not built.

“A type of planning bill that is arranged in product modules or options. It is often used in companies where the product has many optional features, e.g., assemble-to-order companies such as automobile manufacturers”.

It is artificially arranged according to product modules or options. Modules are std. units that can be prepared in advance of receiving a customer order. The fact that modules are std. means that the producer assumes lower risk in their production to stock against a sales forecast. An option is a customer selectable choice from an offered produce feature. Each option or module will be defined fully in BOM as a single level of BOM. Thus the modular BOM’s structure’s architecture links component parts to options but it doesn’t link either options or components to end item configurations. If the options are simply buildable subassemblies, they should be treated as end items. The use of modular BOM reduces the no. of end items scheduled, facilitates order entry & permits more efficient computer storage & system maintenance.