DSP01

Which of the following activities can be included in contract management for suppliers ?

I. Periodic status report.

II. Gantt chart.

III. First article inspection.

IV. Status review meetings.

Which of the following activities can be included in contract management for suppliers ?

I. Periodic status report.

II. Gantt chart.

III. First article inspection.

IV. Status review meetings.

Which of the following BEST explain the characteristics of strategic partnership ?

I. Strategic alliance - business level.

II. Technical and commercial partnership - product level.

III. Operational partnering - part level.

The ABC analysis used for cycle counting is an example of:

Which of the following statements are true regarding time-phased order point?

I. Lot sizing is eliminated

II. It is more effective than order point

III. Uses MRP logic for independent demand

Independent demand can be best defined by which of the following?

Which of the following best defines the term FIFO?

Which of the following is NOT the method accounting use to cost inventory?

What uses cost determined before production begins?

When a small number of items often dominate the results achieved in any situation, this is called:

Which of the following are true regarding cycle counting?

I. All items are counted the same number of times per year.

II. Paperwork cut off is generally more difficult than at an annual physical.

III. Causes of error and correction are more effective than annual physicals.

Which of the following best defines the term "allocation" in an MRP system?

If the beginning inventory value is larger than the ending inventory value, which of the following relationships is true?

Which of the following statements best defines the reason the bill of materials needs to be accurate?

I. Quality problems can occur.

II. Cost analysis will not be complete or accurate.

III. MRP will plan parts incorrectly.

Which documents are (is) regarded as the payment for supplier's goods ? I. Invoice. II. Bill of lading. III. Packing list. IV. Arrival notice.

Lot size should be considered when calculating :

Which of the following is the MOST effective practice for the supplier relationship ?

Calculate the EOQ using the following information.

Annual Demand = 2500 units.

Ordering costs = $ 25.

Carrying costs = $ 2 / unit

Unit costs = $8

As applied to inventories, it is usually found that the relationship between the percentage of items and the percentage of annual dollar usage follows a pattern in which three groups can be defined:

I. Group A About 50 % of the items account for about 5 % of the dollar usage

II. Group B About 20 % of the items account for about 80 % of the dollar usage

III. Group C About 30 % of the items account for about 15 % of the dollar usage

Which of the above statements are true

To order exactly what is needed, no more, no less, this rule is called:

What occurs when the cost of ordering equals the cost of carrying?

The purchase cost of the stock-keeping units or the cost of manufacturing the item is called:

Which of the following best describes the importance of cycle counting?

Which of the following statements is true if there is a lot of variability between planned and actual demand?

I. Safety stock will generally need to be high.

II. The mean absolute deviation will be lower.

III. The delta between plan and actual will be high

Which of the following is required for the successful implementation of JIT ?

What is the rated capacity of W/C 112 when break down of two machines occur ?

Utilization = 90%.

Efficiency = 80%

No. of machines = 6

No. of shifts = 3

Work hours per day = 8 hours

No. of work days per week = 5 days

When completing a project, all are some typical financial savings EXCEPT?

What is a tool that links customer desires through product design to manufacturing performance and process variables?

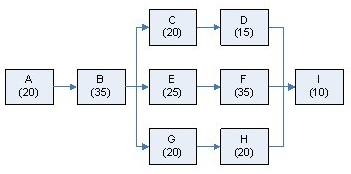

How many days of slack is there in the path A->B->C->D->I using the below network diagram?

In order to have a Kaizan event you must have

I. Small multi - disciplined team

II. Team trained in problem solving

III. Upper Management on the team

A "order to be released" would be what type of MRP Message?

What capacity is established by averaging the actual output produced in standard hours in previous periods?

What is the primary tool to control/ monitor real capacity

The Pancake Store presents the following facts pertaining to the cost of one product carried in its merchandise inventory:

Beginning inventory on hand, 200 units @ $15 = $3,000

Purchase June 1, 200 units @$16 = $3,200

Purchase July 5, 200 units @ $20 = $4,000

Purchase August 25, 200 units @ $25 = $5,000

A new order comes in for 500 units.

What is the cost of goods sold that should be recorded for that new order using the LIFO accounting method?

When goods are received, sorted and then loaded onto an outgoing vehicle without ever going to stock is called what?

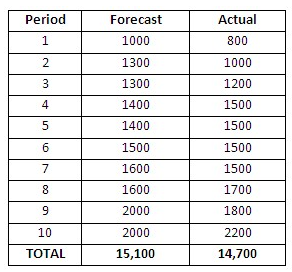

Using the following table, calculate the Mean Absolute Deviation (MAD)

Chris's TV factory has $25,000,000 of stock in the warehouse, and average monthly sales of $35,000,000. What are the days of supply for Chris's TV factory assuming an average 30 days in a month?

Which of the following are lot sizing methods?

I. Fixed Order Quantity

II. Kanban Quantity

III. Agreed Order Quantity

IV. Time Period Ordering

A gross requirement is defined as

Inventory that has no known forecast requirement is called

Stock that production workers can draw from without requisitions is called what?

Bucketless MRP system are generally evaluated more effective than typical MRP system because :

In a transfer line, cycle time of the end item is 36 seconds. How many inventory are carried for customer delivery ? (Projected delivery lead time is 2 hours)

What is the important element for JIT supplier ?

Which of the following is TRUE regarding the timing of preventive maintenance activity ?

Firm planned orders are :

All of the following may increase the complexity of capacity planning EXCEPT ?

Input of CRP is NOT :

________________ uses the economic-order-quantity formula to calculate an economic time between orders.

The formula to calculate the period-order quantity is:

When the quantity of an item on hand in inventory falls to a predetermined level called:

______________ is used to protect against timing uncertainty by planning order releases and order receipts earlier than required.

What have most of the values clustered near a central point with progressively fewer results occurring away from the cluster?

In a fixed order quantity system, which of the following is true? I. The quantity is the same for each order. II. The order interval varies. III. An order is placed when on-hand balance reaches a reorder point.

A company takes a physical inventory. In comparing it to the financial records, they find the physical inventory valuation to be much less than the financial records.

After much investigation, journal entries are made to reduce the financial records to reflect the physical inventory valuation. The adjustment is a(an):

Which of the following are included in the lead time for a part? I. MRP run time II. Order preparation time III. Transportation time

If a company uses a locator system, how would cycle counting be conducted?

I. Physical bin locations would be audited for accuracy.

II. The count of the product in the location would be checked.

III. No check of bin location would be necessary as the computer tracks it.

In an MRP environment, if the lot-for-lot technique is used, which of the following is true?

I. Only net requirements will be ordered.

II. Residual inventory will exist.

III. Of all the lot sizing rules, it creates the least inventory.

Company A uses 100 units of product B each week; however, it must order 500 units for each order of product B. The inventory remaining is called:

All of the following are included in manufacturing lead time EXCEPT:

Under a min-max inventory system, what would the order process be?

The objective of CRP is :

Which of the following is the MOST important factor of JIT to the customer ?

What is the minimum inventory level when the information of a item is as following ?

Demand during lead time = 100 units.

Customer service lever = 99%

Standard deviation = 200 units.

Daily sales quantities are 10 units, standard deviation for sales is 3 units. What is the probability of sales quantities less than 16 units ?

Repetitive manufacturing frequently require MRP systems for :

Information of full pegging provide the planner with which information of the following ?

Which is TRUE about modular BOM ?

I. Segregation common parent from unique parts.

II. Eliminating absolute number of BOM.

III. Simplifying BOM structure.

Which of the following information would be used as the input of MRP and CRP ? (Most Important)

What is the actual capacity of W/C ?

Outputs for 4 weeks = 610 units, 630 units, 600 units, 640 units

Utilization = 80 %

Efficiency = 60 %

Production standard hours = 42 hr / week

Calculated capacity = 44 hr /week

Which of the following is TRUE when increasing MRP planning frequency ?

Lead time for a item = 16 weeks

MAD = 100 units

Forecasting interval = 4 weeks

Customer service level = 95%

Safety stock level of the item is :

Which of the following environment would be the MOST useful for full pegging technique ?

Assemble time per piece = 30 minutes

Utilization = 80%

Efficiency = 90%

How many operators should be required when producing 800 units per 40 hours ?

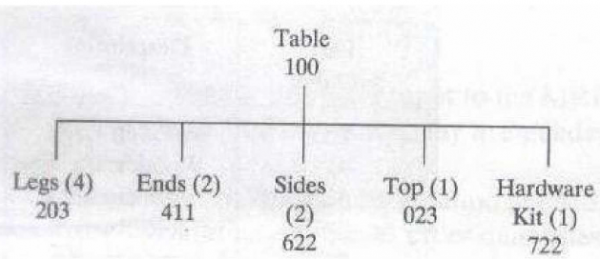

What the following figure shows:

A bill is used when companies usually make more than one product and the same components are often used in several products

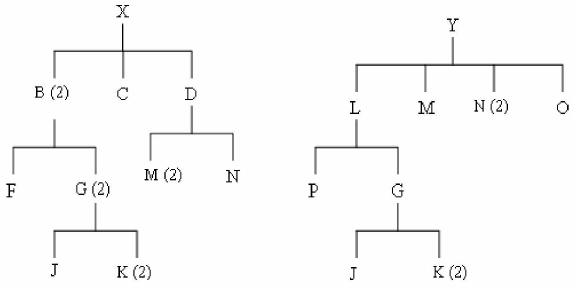

By using following product tree, how many Ks are needed to make 200Xs and 150 Ys?

A multilevel bill of material can shown as

Which of the following is an artificial grouping of components for planning purposes?

Planning bills are used to:

A. Simplify forecasting

B. Master production scheduling

C. Material requirements planning

Planning bill does not represent

Where-used reports give information about

A listing of all the parents in which a component is used is called

A. Pegging report

B. Where-used report

C. Planning bill

A pegging report:

Product design engineers sometimes change the design of a product and the components used. These changes must be recorded and controlled. The bill provides the method for doing so is called A. Engineering change control B. Production change control C. Demand change control

Which of the following defines what materials have to be scheduled to make the end products?

Exploding is the process of multiplying the requirements by:

A. The usage quantity

B. By recording the appropriate requirements throughout the product tress

The process of placing the exploded requirements in their proper periods based on lead time is called

Which of the following is the right calculation for obtaining the net requirements?

Scheduled receipts shows: A. The quantities ordered B. When quantities ordered are expected to be completed C. When quantities ordered are expected to be available

The objective of the MRP is to have:

A. Material available when it is needed and not before

B. Orders for material should not be released until the planned order release date arrived

C. Order should not normally released until the planned order is in the current week

In an MRP environment, if a part has an order policy of lot-for-lot, which of the

following statements is true?

I. In combination with other factors, inventory should be minimized.

II. Order releases will eventually equal net requirements.

III. Order quantities will be equal over time.

Which of the following statements is true about reaching a high level inventory record accuracy?

In cycle counting, an ABC analysis is usually completed to identify the parts with the

highest value or highest volume versus those with the least value or volume. Generally,

80% of the value is about 20% of the parts. This 80-20 rule is based on:

Which of the following reasons could be used to justify maintaining safety stock in an MRP system?

I. Uncertain lead times for raw materials

II. Items used for spare parts which are also used in assembly

III. Component items manufactured in-house have had inventory errors

Which of the following is true regarding the reduction in queue times?

I. They can be achieved by speeding up the equipment.

II. Lead times will be reduced.

III. Work-in-process inventory will decline.

Time-phased order point (TPOP) can be best described as:

Inventory records have not been accurate. Which of the following actions can be taken to restore the accuracy?

In which of the following environments will a statistical order point system work best?

A company is introducing a new product to the marketplace. In order to make the introduction smooth, the inventory manager has built a large inventory for the product prior to the introduction period. Which of the following reasons best justifies this action?

If a company is going to manufacture items during the slack season for use during a busy season, the items chosen should be:

Which of the following environments would be best suited for a statistical order point system?

Which of the following statements is/are true regarding demand?

I. Independent demand is derived from forecasted data.

II. Dependent demand is forecasted.

An order for an item needed in Period 10, with a manufacturing lead time of 5 periods, would have which of the following dates?

In a properly designed MRP system, which of the following objectives can be achieved?

I. Provide input to the capacity requirement planning module.

II. Maintain open order priorities.

III. Manage inventories properly.

The minimum acceptable length of time that a planning horizon should be is:

Which of the following functions is/are the responsibility of the MRP system user?

I. Maintain bill of material accuracy

II. Maintain inventory record accuracy

III. Maintain planned order priority

The MRP output that shows the source of the requirement for a part is called a(an):

Allocation in an MRP environment refers to:

Which of the following is counted during periodic physical inventory?

I. Raw Material

II. Sub Assemblies

III. Finished Goods

IV. Material Received Not in Stock

Which of the following are MRP Pre-requisites?

I. Bill of Materials

II. Inventory Records

III. RCCP

IV. Master Production Schedule

What models would be used for simulation and modeling techniques in the Operations management Planning area?

I. Rough Cut Capacity Planning

II. Capacity requirements Planning

III. Input Output Control

Which finite loading technique plans orders around bottleneck work centers?

Another name for Quality Function Deployment (QFD) is what?

All of the following are product condition measurements EXCEPT

Which of the following provide mutual value to companies and their suppliers?

I. Low Price

II. Time Phased delivery of Goods

III. Concurrent Engineering

What is the Inventory holding costs when

Order Quantity = 100

Unit Cost = $35

Inventory Holding Cost % = 20%

In a flow manufacturing environment, what loading environment would MOST LIKELY be used?

Which of the following is NOT included in Purchasing Lead Time

A safety factor or 3.000 would calculate to what service level percentage?

Which of the following are partnerships at the product level?

I. Strategic Alliance

II. Technical Partnering

III. Commercial Partnering

IV. Operational Partnering

Backlogs should be held:

In order for JIT purchasing to be truly effective, which of the following factors need to be

in place?

I. The supplier base needs to be reduced.

II. Single source suppliers need to be used.

III. The supplier must be willing to hold the inventory.

IV. The schedule needs to have some stability.

Which statement is true about the objectives of inventory management?

Company A's purchasing department has been negotiating with a vendor for product 123. The vendor has suggested the company commit to 20% of the vendor's output over the next six months. This practice is known as:

The field service technicians order replacement parts for repair purposes. This is an example of:

Providing suppliers with an MRP planning report allows the suppliers to do which of the

following?

I. Reduce the cost of raw materials

II. Schedule their plants more efficiently

III. Stabilize their workforce

When the MRP reports are provided to suppliers for use in their planning, the planned orders from those reports become the supplier's:

The automatic updating of scheduled receipts by the computer should be used when:

The major benefit for a supplier to develop a strategic alliance with a customer is:

Often, companies will use cross-functional teams to develop new designs and get products to market. These cross-functional teams will very often include the appropriate suppliers in the design. This allows the product development activities to overlap each other, thereby, shortening the product development time. This process of overlapping activities in the product development cycle is called:

A disciplined effort to compare the function performed by an item and its cost in an attempt to find a lower cost alternative is called:

The process of supplier evaluation rates suppliers on their ability to meet price targets, quality specifications, and:

It is important to maintain a close relationship with certified supplier partners. The most difficult part of establishing a supplier partnership is:

In recent years, many companies have become assemblers of their products where in the past they may have manufactured many of the subassemblies, as well. This trend towards having many large sections of the product assembled outside the manufacturer's primary operation is called:

When a supplier has been certified and has been reliably delivering products to a company, often times the company will develop a process, whereby, purchase orders are no longer necessary. The product will arrive at the dock, bypass inspection and counting, and be delivered to the production line. This delivery location on the production line is called a:

Sometimes, a supplier will consign inventory to a location on the production line of the customer. The customer will then use the product and pay for the materials used each week. This method of inventory management is called:

The mission of the purchasing department is to identify and qualify adequate sources of competitively priced supply to manufacture the products required by the marketplace. Many times, this mission includes identifying sources regardless of their location. This is called:

In order for a supplier to supply in a JIT manner, meeting the schedule with the right products at the right time, which of the following is imperative?

One solution to minimize costs when getting small frequent deliveries from suppliers would be to utilize backhauling. Which of the following best defines backhauling?

Sometimes, the more distant suppliers will absorb the additional freight charge to match the freight charge of the geographically closer supplier. This practice is known as:

A supplier who consistently meets predetermined quality, cost, delivery, financial, and quantity objectives will generally be awarded:

A company has short product life cycles and consequently, experiences significant obsolete inventory write-offs annually. Of the following methods, which of the following would not be an effective handling of the obsolescence

Which of the following is not included by planning factors using the item master record?

Standard costs are generally established before actual production in a standard cost system. Using this system, how would management determine how well goals are achieved by production?

A company has an annual requirement of 2,000 units for a part. How many exposures does this company have if it places orders in the quantity of 400 and maintains a safety stock of 0?

The Indoor Store presents the following facts pertaining to the cost of one product carried in its merchandise inventory:

Beginning inventory on hand, 200 units @ $15 = $3,000

Purchase June 1, 200 units @$16 = $3,200

Purchase July 5, 200 units @ $20 = $4,000

Purchase August 25, 200 units @ $25 = $5,000

A new order comes in for 500 units. What is the cost of goods sold that should be recorded using a simple weighted average using the LIFO methodology?

All of the following are techniques to reduce lead time EXCEPT

Which of the following are basic process flow scheduling approaches?

I. Vendor Dominated Scheduling (VDS)

II. Processor-Dominated Scheduling (PDS)

III. Material-Dominated Scheduling (MDS)

Today- what is NOT a major issue with supplier partnerships?

During an inflationary period, which of the following would NOT be associated with LIFO inventory valuation?

I. Increase Cost of Goods Sold

II. Decrease Cash Flow

III. Increase Profits

All of the following ensures capacity availability matches demand in the following areas EXCEPT

What equals direct time charged/ clock time scheduled?

Although the primary role of the MRP system is often assumed to be balancing supply and demand through the time phased netting process, which of the following is the other major function of MRP?

The acceptable tolerance of error associated with physical inventory is generally limited to which of the following?

Which of the following definitions best matches the term "equal runout quantities"?

Some industries have inventory carrying costs as high as 40%, sometimes they are even higher. Which of the following items is not included in calculating the carrying cost?

Which of the following is not an input from another system required by Capacity Requirements Planning?

On what should emphasis be placed if the priority system is to be effective?

Which of the following demand patterns works most effectively with a reorder point system?

It is acceptable to manage obsolete inventory in which of the following ways?

I. Holding write-offs until after year end to keep profits up

II. Accruing the same write-off each month to smooth the financial impact

Which of the following is false regarding the lotfor- lot technique when used in an MRP environment?

Which of the following is a true statement concerning the fixed order quantity system?

I. An order is placed when the reorder point is reached by on hand balance

II. The order interval varies

III. Quantity for each order varies widely

A statistical order point system would be best applied in which of the following company environments?

What is the order process when using a min-max inventory system?

Which of the following is attributed to a useful load projection?

I. It is based on priorities which are valid

II. The load on the factory is complete

III. It provides visibility into the future

Using the data below, determine the reorder

point.

On hand balance = 200

Weekly usage = 200

Leadtime = 3w

Safety stock = 100

Which reason below has the most impact on the need for inventory record accuracy?

Which of the following choices reflects a pair of requirements necessary to calculate safety stock?

I. Customer service level needed and annual demand for the part

II. Actual versus forecast differences and annual demand for the part

III. Customer service level needed and actual versus forecast difference

The need for expediting can be minimized by which of the following?

All of the following are objectives of cycle counting EXCEPT

Michelle's diaper company is trying to determine the Target Inventory Level for their best selling diapers. With the following information, what is the target inventory level?

Lead time = 2 weeks

Forecast = 40 per week

Review period = 4 weeks

Safety Stock = 50

Which of the following would NOT be included in top management planning?

What are the ways to measure variation in demand

I. Standard Deviation

II. Factor Deviation

III. Mean Absolute Deviation

Actual lead time is directly affected by what?

What are the three areas of simulation?

I. Lot Order Sizing

II. MRP as a simulator

III. "What If" Facility

IV. Linear Programming

Holding Costs Include all of the following EXCEPT

What is defined as the amount of planned work scheduled for and actual work released to a facility, work center, or operation for a specific span of time?

A purchase order is signed with ABC company for $3,000 worth of materials. The average salary of a buyer is paid $25 an hour and manufacturing gets paid $20 an hour.

It takes 5 hours for a buyer to set up a purchase order and it takes manufacturing 10 hours to set up the job and 40 hours to process the job

How much are the ordering/ setup costs for this purchase order

For a make to stock environment, when the part has passed final inspection and booked to stores it becomes what?

The difference between Projected Available Balance and Projected On-Hand Balance is that Projected On-Hand Balance what?