Distribution Requirement Planning

As MRP became more popular it was recognized that the order point could be setup in a MRP format. This was originally called the TPOP but that was just a term to help people who had learned that ‘order point applies to independent demand items’ bridge the gap in learning, & understand that MRP applies to independent items too!. The fact of matter is that the MRP format applies whether demand is independent or dependent. TOP is merely a synonym for MRP – for independent demand items.

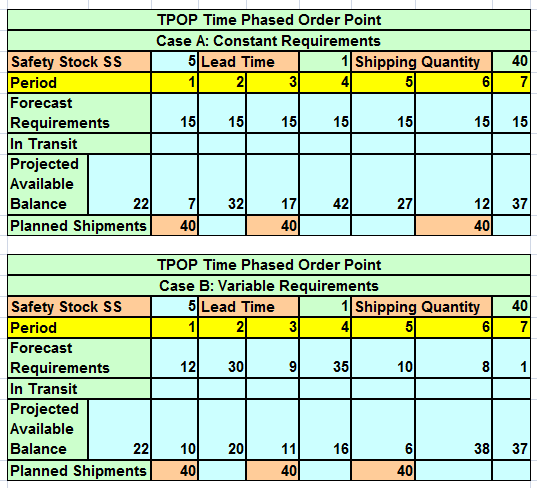

The time-phased order point (TPOP) is used for the planning & control of independent demand is not continuous. In some situations such as MPS & DRP, TPOP can be used when demand is continuous. TPOP is used for FGs and service parts. The order point is a misnomer in that this technique does not calculate a specific order point. Time phasing is the segmenting of inventory status by time periods.

The TPOP for independent demand at distribution centers is called distribution requirement planning. Anything that is going to be distributed has to be made & today DRP is seen as simply an extension of MRP.

The demand in a TPOP system may be forecasted or based on customer orders & is listed as the Gross Requirement. Gross requirements are listed by time period over the horizon of the palling period. The available inventory is also listed by time period with the projection based on forecasted demands (gross requirements), as well as open & planned order receipts. The Net requirement for the period is calculated by subtracting the projected available inventory from the gross requirement. The order quantity may be based on a fixed period, such as every 2 weeks, or a fixed quantity, such an EOQ of 100 units.