Demand management in MPC system

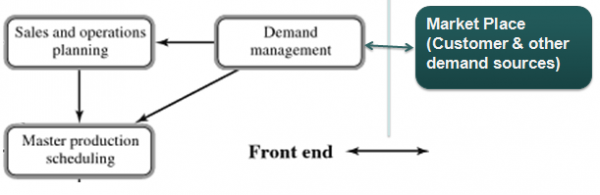

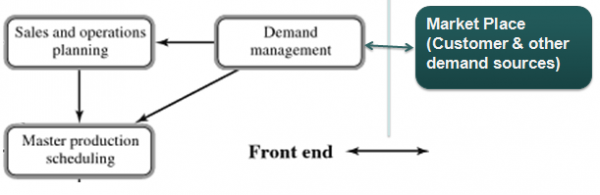

The position of the demand management in the MPC is shown in the above fig.

The position of the demand management in the MPC is shown in the above fig.

It is the key connection to the market place in the front end of the MPC system.

The Demand management is a gateway module in MPC system, providing the link to the market place, SOP & MPS. The communication between DM & market place are two way communications - gathering information from the customer & informing customer the status of the order.

The information provided to SOP is used to develop sales & operation plan covering a year or more in duration at a high level of aggregation. Both the sales order & forecast information is provided to the MPS system. It is in the MPS system that short-term, product specific manufacturing plans are developed & controlled as actual demand becomes available and information is provided to the provide delivery promises and order status to customers.

Planning & Control

Distribution System

The overall goal of a distribution system is to provide products & services in an efficient, timely &

cost-effective manner to multiple customers.

Distribution of products often creates a hierarchy of stocking locations. These include manufacturing

centers, distribution centers, wholesalers & retailers. These locations constitute the supply chain from

original producer to ultimate consumer.

The distribution of goods is also often referred to as logistics a term used in military to denote the planning & delivery of inbound & outbound materials.

Logistics 1) In an industrial context, the art and science of obtaining, producing, and distributing material and product in the proper place and in proper quantities.

2) In a military sense (where it has greater usage), its meaning can also include the movement of personnel”.

Factors Influencing Distribution Network Design

At the highest level, performance of a distribution network should be evaluated along two dimensions:

1. Customer needs that are met

2. Cost of meeting customer needs

The customer needs that are met influence the company's revenues, which along with cost decide the

profitability of the delivery network.

While customer service consists of many components, we will focus on those measures that are

influenced by the structure of the distribution network. These include:

• Response time

• Product variety

• Product availability

• Customer experience

• Order visibility

• Returnability

Response time is the time between when a customer places an order and receives delivery. Product

variety is the number of different products / configurations that a customer desires from the

distribution network. Availability is the probability of having a product in stock when a customer

order arrives. Customer experience includes the ease with which the customer can place and receive

their order. Order visibility is the ability of the customer to track their order from placement to

delivery. Returnability is the ease with which a customer can return unsatisfactory merchandise and

the ability of the network to handle such returns.

It may seem at first that a customer always wants the highest level of performance along all these

dimensions. In practice, however, this is not always the case. Customers ordering a book at

Amazon.com are willing to wait longer than those that drive to a nearby Borders store to get the same

book. On the other hand, customers can find a far larger variety of books at Amazon compared to the

Borders store. Firms that target customers who can tolerate a large response time require few locations that may be far from the customer and can focus on increasing the capacity of each location. On the other hand, firms that target customers who value short response times need to locate close to them. These firms must have many facilities, with each location having a low capacity. Thus, a decrease in the response time customers desire increases the number of facilities required in the network.

Distribution System Objectives:

The overall goal of a distribution system is to provide products & services in an efficient, timely &

cost-effective manner to multiple customers. This goal can be linked to the following objectives:

High Levels of customer service:

· Timely delivery lead times in accordance with customer expectations.

· Buffering against uncertainties in customer demand.

· Providing the necessary variety of goods, including display & sample products.

High Levels of Distribution Efficiency:

· Minimum transportation & storage costs for optimum distribution efficiency.

· Level production of replenishment orders to minimize disruption at the suppliers.

· Size & location of storage.

· Provision of timely & accurate inventory data.

Minimum Inventory Investment:

· Minimum necessary safety stock.

· Optimum order quantities to control excessive cycle stock.

VMI & Consignment Inventory

VMI

In VMI a manufacturer or distributor assumes the role of inventory planning for the customer. Extensive information sharing is required so that the manufacturer/distributor can maintain a high degree of visibility of its goods at the customer’s location. Instead of the customer reordering when its supply has been exhausted, the supplier is responsible for replenishing and stocking the customer at appropriate levels. Wal-Mart has mastered VMI and is the company against which many other organizations benchmark themselves (1).

Steps in a VMI process

For better understanding they describe the VMI business model as follows:

- The manufacturer receives electronic data (usually via EDI or the internet) that informs him about the distributor’s sales and stock levels.

- The manufacturer can view every item carried by the distributor and point of sales data.

- The manufacturer is responsible for creating and maintaining the inventory plan.

- The manufacturer generates the order, not the distributor (But this doesn’t change the ownership!)

Customer Benefits

When the supplier can see that its customer is about to exhaust its inventory, the supplier can better prepare to replenish the customer because the supplier can then better schedule its own production/distribution. Customers will reduce/eliminate stockouts because they will not have to reorder goods at the last minute without knowing whether the supplier has the ability to restock without interrupting the customer’s operations. Therefore, part of VMI’s goal is to reduce uncertainty that arises when the supplier is blind to the customer’s inventory status.

Supplier Benefits

As long as the supplier carries out its task of maintaining predetermined inventory and avoiding stockouts, it will be able to lock in a VMI-supported customer for the long term with or without a contract. This will produce a steady and predictable flow of income for the supplier and reduce the risk that the customer will switch suppliers (Switching would be too costly for the customer). A VMI arrangement will allow the supplier to schedule its operations more productively because it is now monitoring its customer’s inventory on a regular basis. Furthermore, reductions in inventory will be achieved once the supplier develops a better understanding of how the customer uses its goods over the course of a year.

Consignment Inventory is inventory that is in the possession of the customer, but is still owned by the supplier. In other words, the supplier places some inventory at the customer’s location. The customer purchases the inventory only after he has resold or consumed it. The liability of loss, damage, obsolescence and theft remains with the supplier.

As a manufacturer you may have consignment inventory at your customers and you may also have to contend with consignments from your Vendors. Most ERP systems have difficulty with consignment inventory. With consignment inventory the invoicing is not tied to the shipment or receipt transaction. This requires companies to manage consignment inventory with cumbersome time consuming and error prone processes. Typically both the Customer and Vendor maintaining separate spreadsheets. There are several trigger points to the actual ownership transfer and billing transaction:

- Invoice when product is actually used or sold

- Invoice after a pre-defined period

- Invoice when used or after a pre-defined period - which ever comes first

- Invoice when next consignment order is placed, previous is billed

.

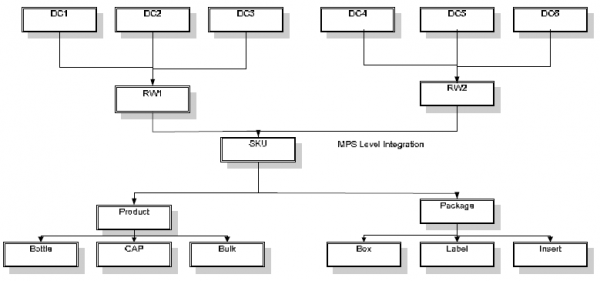

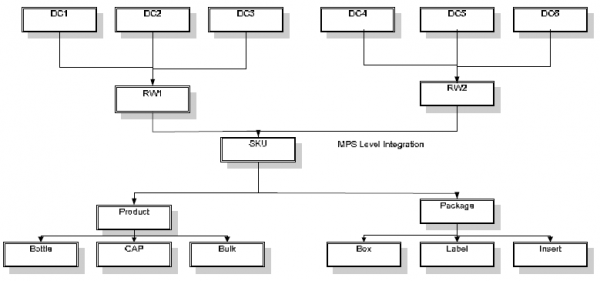

Bill of distribution

The bill of distribution (BOD) specifies how a product is further distributed within your enterprise following inward delivery from the supplier before being passed on to the customer. The concept is similar to the way BOM links component items to their assembly parents. In case of BOM when a demand is posted on a parent assembly item the MRP processor references the assembly’s BOM & explodes the requirement through the product structure, placing demand on the component parts. In case of BOD the structure had been designed to facilitate the transfer requirements from the components (the satellite warehouses) to the parent (the supplying warehouses).

This structure is often called as an inverted BOM performs an implosion whereby requirements are passed up the structure rather than down. A BOD can be configured exactly to match a variety of channel inventory flows, E.g. not all items may be stocked in every warehouse. Again a mixture of products might be sold to the customer from central warehouse or from several regional or even local distribution points.

For DRP implosion to work effectively the proper BODs must be structured to details the flow of each product in the distribution channel.

The DRP & MRP system interface at the master production schedule level. The forecast of product demand filtered through the distribution plan, should be the major contributor to the master schedule. The master schedule can check distribution capacity as part of the rough cut capacity planning feasibility check.

Safety Stock and DRP

- When there is more uncertainty in terms of timing, then it may be better to use safety lead time. A safety lead time is “an element of time added to normal lead time to protect against fluctuations in lead time so that an order can be completed before its real need date. When used, the MRP system, in offsetting for lead time, will plan both order release and order completion for earlier dates than it would otherwise

- When the uncertainty is in quantity then safety stock may be better.

- Carry safety stock where there is uncertainty (near the customer).

The position of the demand management in the MPC is shown in the above fig.

The position of the demand management in the MPC is shown in the above fig.