ECO002

A "healthy" work-in-process inventory can be generally defined by which of the following statements?

I. Three days

II. Twenty five percent of finished goods

III. The minimum amount needed to smooth fluctuations in input

A "healthy" work-in-process inventory can be generally defined by which of the following statements?

I. Three days

II. Twenty five percent of finished goods

III. The minimum amount needed to smooth fluctuations in input

The time period which exists between the completion of one operation and the start of the next operation is:

Which of the following is associated with backward scheduling?

A "healthy" work-in-process inventory can be generally defined by which of the following statements?

I. Three days

II. Twenty five percent of finished goods

III. The minimum amount needed to smooth fluctuations in input

The time period which exists between the completion of one operation and the start of the next operation is:

Which of the following is associated with backward scheduling?

Which of the following is/are needed in order to calculate manufacturing lead-times?

I. Routings

II. Interoperation times

III. Component purchase lead time

Which of the following are true regarding operations scheduling?

Which of the following is affected when input does not match output?

I. Lot sizes

II. Lead times

III. Queue sizes

Which of the following best describes back scheduling?

When orders are assigned to the factory without any restrictions on capacity, this is known as:

Product A can be produced at the rate of 60 per hour or one each minute. This time is known as the:

Which of the following is synonymous with detailed scheduling?

The primary purpose of a dispatch list is to display the:

An order for 1000 parts is due 2 weeks from now. The historical scrap factor for this part is 5%. Based on this, the expected completion quantity will be:

Which of the following best describes a focused factory?

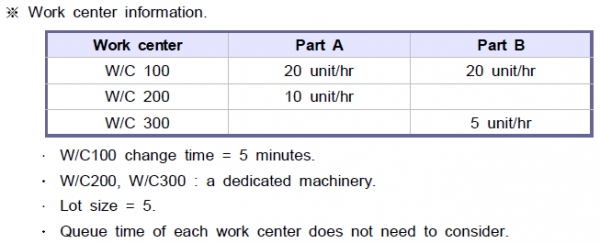

What is the time for the production of a lot of Part A when the information of this calculation are as the follows ?

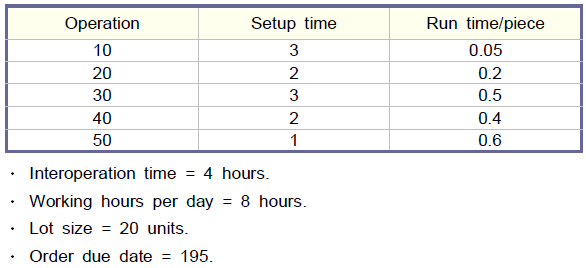

Using the routing information of order A, when is appropriate for the working start date of operation 20 ?

Calculate overtime per day per worker :

Available hours per week : 40 hours.

Utilization : 90%.

Efficiency : 80%.

Lot size : 1000 units.

Cycle time per work = 15 minutes.

No. of workers = 4.

Required production time = 2 weeks.

A company has 500 units of week demand and 8 days of transit lead time. In case of the product price for this demand is $25 and carrying cost rate is 20%, how much cost reduction is expected when decreasing transit lead time from 8 days to 5 days ?

When using the below information, calculate the rated capacity if increasing 10% of the productivity.

No. of machines : 10.

No of shifts : 2.

Workers per shift : 1 shift - 8 workers. 2 shift - 5 workers.

Utilization = 80%.

Efficiency = 90%.

Working hours per week = 40 hours.

Which of the following technique can contribute to intensify visual control for a specific workcenter ?

Zone location system have some advantages such as :

I. Reduction of material handling.

II. Proximity for related parts.

III. Travel cost effectiveness.

IV. Utilization of branch warehouse.

Which of the following is likely to most appropriate practice for WIP inventory accuracy ?

If critical ratio is 0.5, controller should :

PLUSSTAR , power supply production company, has two product lines. One is made to contribute

part fabrication and another is used to assemble parts, but now the company have some problems for

second line - excess inventory and part shortage. Which of the following measures is the BEST choice for

improving this line ?

If gateway work center is overloaded, what should be done for next operation by controller ?

If efficiency of a workcenter have just improved from 80% to 90% and other parameter affecting workcenter capacity are the same, what is input having same queue ? (assuming the prior input is 680 units.)

EDI or electronics transaction can eliminate :

Among problem solving techniques, "Priority" is the closest relationship with

Setup cost is set by

All of the following affect on rescheduling shop order EXCEPT

Which of the following represent the process in control ?

The process of work are sequential and processing time are 10 seconds, 30 seconds, 20 seconds, 40 seconds, 30 seconds, 20 seconds respectively. When the required production rate is one unit per minute, How much workers are needed ?

When a company select backflusing as inventory control system, a company have some problems concerning to

Which of the following statements are generally included in a routing?

I. Operations to be performed and their sequence

II. Work centers involved in manufacturing

III. The raw materials needed to produce

Generally speaking, which of the following would represent the largest portion of lead time?

Which of the following could be done to reduce manufacturing lead times?

I. Add a shift to the operation

II. Improve setup times

III. Reduce queues in front of work centers

Because of the flow system and the low work-in-process inventory,

Goods are not made continuously as in a flow system but are made at intervals in lots or batches in:

When there is no distinction between locations such as store rooms and material arrives and is processed through the plant into finished goods without ever entering a formal stock area is called what?

Some disadvantages of Acceptable Quality Level are what?

I. Sometimes accept bad materials if under AQL

II. Only identifies defects, does not resolve them

II. Stops bad batches of materials during incoming inspection

Rick's manufacturing shop produces sheet metal with pre cut holes for its customer. The holes in the sheet metal must be a very specific diameter for the customer to use the product. Rick has been implementing some changes that seem to be working. He now wants to see if the process is becoming even more erratic or more stable than before. What type of statistical process control chart should he use?

Calculate the critical Ratio with time remaining 48 hours. Total queue and move time 32 hours and total operation time 30 hours of operation time.

According to Shingo, describing the Toyota Production System, says that synchronization never works without what?

The objective of six sigma is to what?

What is used in the Toyota Production System?

Which of the following is NOT a basic element of product cost?

Which of the following reporting levels would support CRP planning?

What is the number of kanban production cards in circulation for an item controlled by the dual card kanban system given the following information?

Plant works 10 hours a day

Planned usage is 650 per day

Each container contains 75 parts

Manufacturing lead time is 3 days

Wait/ queue time for the lot to be started is .5 days

Which of the following is not an influence on plant capacity?

The manufacturing calendar in a company's manufacturing system defines weekends as nonwork days. Given this, how many weeks would represent a 35 day lead time?

Of the following business environments, which would best apply shop floor control procedures?

A part is produced by a company’s department in 4 operations. Last month, the department’s earnings were 1,500 standard hours by producing 1,000 parts. The department worked 1,000 hours to produce these parts. Which of the following accurately defines the department’s efficiency?

When throughput time expands and the work center bottlenecks, which choice below is not a viable remedy?

Which of the following is an important consideration in choosing a Just-in-time delivery system carrier?

Of the following statements, which is true of first piece inspection?

For what is the bar code data collection system used?

Idle time is directly caused by which of the following?

A flexible manufacturing system provides which of the following benefit pairs?

Which of the following defines fixed cost?

Incoming inspection is not required from a certified supplier for which of the following reasons EXCEPT:

Small lot manufacturing reduces which of the following pairs?

A work center receives more input than output. Which of the following effects will be a result of this situation?

Which of the following definitions best matches the term bottleneck operation?

In regards to input/output control, which of the statements below is true?

Which of the following is not included in shop floor control functions?

Which of the following effects result from overproduction waste?

When a set-up procedure occurs while a machine is not operating, it is called:

When a setup procedure occurs while a machine is running, it is called:

Which of the following statements are true regarding Just-in-Time production?

I. Only refers to the delivery of products when needed

II. Refers to the elimination of waste - "If it doesn't add value, it's waste; eliminate it"

III. It is a pull system

Which of the following statements is true regarding labor productivity?

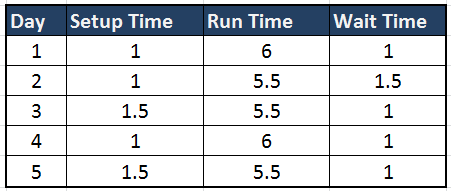

Based on the following information, calculate the machine utilization for a 5-day week based on 8 hour shifts. (Times are expressed in hours.)

Which of the following are scheduled in manufacturing lead time?

I. Time to purchase

II. Queue time

III. Run time

If the manufacturing calendar in the manufacturing system defines weekends as nonwork days, then a 35 day lead time is equal to:

Which of the following is true regarding an open order?

I. It is a released manufacturing order

II. It is a scheduled receipt

III. It is an unfilled customer order

By increasing the capacity at the bottleneck work center, which of the following will

occur?

I. Manufacturing lead times will be shortened

II. Work in process inventory will be reduced

III. Scrap will be reduced

Which of the following methods is the fastest method for adding capacity?

In which of the following businesses can shop floor control procedures be best applied?

I. Make-to-stock

II. Make-to-order

III. Assemble-to-order

When a machine center is being re-tooled and the job is waiting for the center, this time is known as:

Floor stocks can be best defined as:

Major benefits of a flexible machine center include which of the following?

I. Quick changeovers

II. Multiple products to be manufactured

III. Quick setups

Which of the following are valid methods of relieving inventory?

I. Post-deduction transaction

II. Pre-deduct transaction

III. Direct-deduct transaction

Flow control systems are best used in:

Which of the following reasons could exist for an unplanned issue?

I. Material scrapped has to be replaced.

II. Material is being used which is not on the bill of materials.

III. The pick list quantity must be changed

The needs of sales and the economics of production must be balanced, and this balance is usually obtained with:

What exist because of the time needed to move goods from one location to another such as from a plant to a distribution center or a customer?

When in a given period, actual demand will vary about the average demand, this is called:

The new approach to monitoring efficiency includes three priorities. The first priority is to make only what is required by the MPS, the second is to increase the quality level and what is the third?

Which of the following is NOT a quality management principle under ISO9001:2000

What are ways to work with suppliers without the use of a purchase order?

I. Manufacturing Order

II. Release schedule

III. Kanban System

In MRP software packages there are two types of messages given. Action messages and Exception messages. What is an exception message?

An affinity diagram is what type of tool?

What is part of the Just-in-time philosophy is a Japanese term to level production through the supply chain to match the planned rate of end product sales?

If the product is high variety and low volume, the best manufacturing environment would be what?

Allowing operations to draw stock without a requisition is called what?

What type of order environment is MOST associated to mixed model production?

For dispatching to be effective needs the following options and facilities

I. Shop orders are created and maintained to cover requirements

II. Scheduling logic is needed to create start and due dates per operation

III. Only dispatch when a customer order is released

IV. Tracking of order movements is provided

In flow shop sequencing, what would go to the front of the sequence?

What is also referred to as the points of contact, or communication links, between two systems or departments of an organization?

What can hold up to 128KB of data and has a battery powered transponder?

What are the two items quality can control to make a better product?

I. Reduce Variation

II. Improve Processes

III. Implement JIT

IV. Reduce set up time

An operator in a factory sees the next operation has not set their kanban card, yet the operator is sitting idle and has the appropriate materials to start assembling the next product. What should the operator do?

Which of the following is a reason to have cross functional workers?

On-line transaction processing can improve the timeliness of which of the following?

I. Information updating to on-hand balances

II. Recording accurate quantities on receipts

III. Problem resolution

In statistical Process control Cpk is a measure of what?

Which of the following is not included in the total time needed for an operation?

What must decide the market segment to be served, the product features and quality level expected by that market, the price, and the expected sales volume?

Which of the following is part of the lean production philosophy but NOT a part of the Just-in-Time Philosophy?

Dissimilar machines are often grouped into U shaped cells. Which of the benefits below are not derived from this type of arrangement?

What is defined as the hours of slack remaining within the job divided by the Remaining planned queue time

Radio Frequency ID (RFID) is also known as what?

What are the causes the most expense in manufacturing?

To monitor the manufacturing process, what are used?

In process flow scheduling what is a process unit?

Jim is in a room where many of his colleagues are shouting out ideas on a topic with no holds barred on what fist comes to mind about the topic. Jim is sitting in on what type of meeting?

What costing method collects the costs incurred by time period and the concept of an equivalent unit of production?

What does the C stand for in PDCA?

A traditional plant layout grouping like machines together is typically associated with what type of operation?

Which file holds a record for each active manufacturing order, and holds information relevant to the total order?

The objective of set up time reduction is to reduce set-up times to be below what?

When lot size equals 50, unit time equals 1 hour, and set up time is 2 hours; what is the operation time for this scenario?

A push system is defined as all of the following EXCEPT

Scrap planning can be handled in several different ways. Can have a scrap allowance, use a scrap percentage, and what else can be used?

Which of the following is not a data collection technique

What is a term used to describe a specific production control system that is based primarily on setting production rates and feeding work into production to meet these planned rates?

What can help give an employee more flexibility in the jobs they do at a company?

I. Job Rotation

II. Job Enlargement

III. Job Enrichment

When a company has employees sharing the responsibility for problem solving and everyone is involved in making it happen would be a company focusing on what?

What is a system to maximize the throughput of a resource?

An Ishikawa diagram tries to show what?

If a process requires 100 units of input to produce 98 units, its yield is:

Which of the following are true regarding a limiting operation?

I. It is the operation with least capacity

II. It defines the capacity of the line

III. It is the bottleneck

A supplier is responsible to provide 100% acceptable quality to the customer. This is called:

Production order 650 is for 500 of part 3009. From the routing file, it is determined that the setup time is 3.0 hours and the run time is .25 hours per piece. What is the required capacity for this part?

An order for 200 of a product is processed on work centers 101 and 102. The setup time on work center 101 is 60 minutes and the run time is 3 minutes each. The setup time on work center 102 is 50 minutes and the run time is 5 minutes each. The wait time between each operation is 3 hours and the move time between 101 and 102 is 30 minutes. The wait time after work center 102 is 4 hours with a move time to storage of 20 minutes. What is the total manufacturing lead time for the order?

In order to accurately report shop floor data, which of the following must be in place?

Managing the shop floor more effectively can improve customer service in which of the following ways?

I. Replenishing stock orders on time

II. Improving parts availability

III. Improving inventory accuracy

Plant capacity is affected by all of the following except:

Which of the following is the primary function of a supplier scheduler?

In a JIT environment, the production control function is accomplished by:

If a purchased part needs to arrive prior to the original due date in order to meet a delivery date, which of the following should be attempted first?

To effectively capture data on the shop floor, which of the following is needed?

Shop capacity is directly affected by which of the following?

I. Operator efficiency

II. Number of released orders on the floor at one time

III. Number of shifts operating

IV. Level of maintenance

Repetitive manufacturing environments are characterized by which of the following?

I. Use of schedules instead of work orders

II. Consistent flow of finished products

III. Inventory issue transactions used for inventory

All of the following are part of starting a Just-in-Time implementation EXCEPT:

The process of shutting down a production line or machine upon identification of a defect is:

An andon is a:

Which of the following are reasons why setup reduction is so important in a flow manufacturing environment?

I. It allows small lots of many models to be produced on the same line.

II. Costs are reduced although changeovers are frequent.

III. Raw material inventory is kept higher to allow for frequent changes.

Preventive maintenance is important in all companies, but is usually the smallest portion of the maintenance budget. For a lean manufacturing environment, preventive maintenance is critical for which of the following reasons?

I. Unplanned downtime due to breakdowns is avoided

II. It allows the production line to produce saleable units

III. It extends the useful life of equipment, thereby delaying investment in new equipment

Which of the following reflects the order in which Computer Integrated Manufacturing (CIM) should be implemented?

The phrase "one less at a time" refers to which of the following?

For which cost variance would a foreman not be responsible?

Which of the following are not included in manufacturing lead time scheduling?

To add capacity, which of the following methods would be the fastest?

In a manufacturing firm, a product requires a standard amount of material for 20 units. After the first production run, 22 total units of material are consumed. What are the 2 additionally consumed units best known as?

A work center finishes machining a product. To prepare for running another product at the same workstation, they must install different tooling. What is the term used to refer to this process?

Which of the following causes idle time?

Which definition below best matches the term critical ratio?

Parts can be standardized with help from which of the following?

Which of the following statements is NOT true of a work center in which the input is equal to the output?

In a Just-in-time manufacturing environment, the cost system should do all of the following EXCEPT:

Which of the following terms refers to a setup procedure that occurs when the machine is not operating?

Which of the following aid in effective shop floor data capture?

What is the purpose of conducting small group improvement activities (SGIA)?

Which of the following processes occurs when components are deducted from inventory by exploding the bill of materials times the production count of the finished assemblies?

A supplier scheduler serves to accomplish which primary function?

Considering that packaging is critical in the Just-intime delivery process, which of the following should be taken into account during package design?

Which of the following is not an important consideration when selecting equipment to purchase for a lean manufacturing environment?

Which of the following manufacture types is best for the use of flow control systems?

Which of the following definitions best fits floor stocks?