Forecast Performance

Companies striving for operational excellence and a competitive advantage realize the impact forecasting has upon the ability of a company to satisfy its customers and to simultaneously manage its resources. Effective forecasting helps management resolve the dilemma of more demanding customer requirements and greater shareholder expectations. To resolve this dilemma, managers are expected to provide better customer service with fewer resources. In this environment, the importance of effective forecasting is elevated. In manufacturing and distribution companies, a forecast is not simply a projection of future business; it is a request for product (or a request for resources to ensure supply of a product). In simple terms, this is how the forecast works: If a product is in the forecast, you can expect the product (or resource) to be available. If it is not in the forecast, you should not expect the product

to be available. With this concept of a forecast as a request for product, forecast accuracy becomes crucial to ensuring satisfactory, or exemplary, customer service. Forecast accuracy also becomes critical to the proper utilization of resources. For example, when product is requested and not sold or the sale is delayed, resources have been tied up unnecessarily. When a product has not been forecasted but the company must still meet the customer demand, often this is accomplished at a considerably higher cost – a poor use of resources.

First and foremost, we need to measure forecast accuracy if we wish to improve. Measurements are used to make improvements to the specific forecast as well as to the demand planning process. An effective demand planning process measures forecast accuracy in different ways for different purposes. A detailed measure of forecast accuracy at the item level identifies individual products that are outside an established tolerance. This enables us to review – and correct – the individual product forecasts. The earlier a significant forecast error is identified, the quicker we can respond to the real market demand.

Aggregate measures at a product family level are used to determine whether there is a problem with the total (aggregate) product forecast. When a problem surfaces, a more detailed forecast review can be initiated. An aggregate measure is also used as an indicator of the quality of the forecast. It answers the following questions:

Is the forecast reliable?

Is the forecast getting better or worse?

Does the demand planning process need attention?

The aggregate forecast is the sum of the individual item forecasts. As such it also serves as a test for reasonableness. Further, it is used to quantify the overall marketing,sales and business plans. A recurring forecast problem is an indication of a poor demand planning process or, possibly, a tremendously uncertain market.

If the company has an effective demand planning process and significant product forecast errors persist, then a review of tactics and strategies to deal with the uncertainties is required. Since actual customer demand will almost always vary from the forecast either in quantity, timing, or both, it is necessary for companies to have tactics and strategies to deal with these variations. These tactics and strategies include: carrying a buffer inventory, varying delivery lead time, maintaining the ability to flex capacity, and managing demand. Most companies utilize a combination of these approaches. However, it is important that the approach chosen occurs through a managed process.

Because these decisions have considerable impact on customer service, cost, and resource requirements, it should not be left up to chance which tactics or strategies are utilized. Sales and Operations Planning is the management process used by many companies to ensure a managed approach to these tactics and strategies.

Measurement Criteria - An effective forecast measurement process meets certain criteria:

1. It should be “owned” by those responsible for achieving the forecast. Sales and Marketing should develop (or at least agree with) the measurement methodology.

2. The forecast measurements should be easily understood. Unfortunately, it is common to find forecast measurements that are so complicated that sales and marketing simply disavow the validity of the measurement and, thereby, take no accountability for the forecast.

3. The measurements should identify forecast problems quickly and easily at both the aggregate and detail levels which helps to prioritize items requiring forecast review.

Measuring Forecast Performance

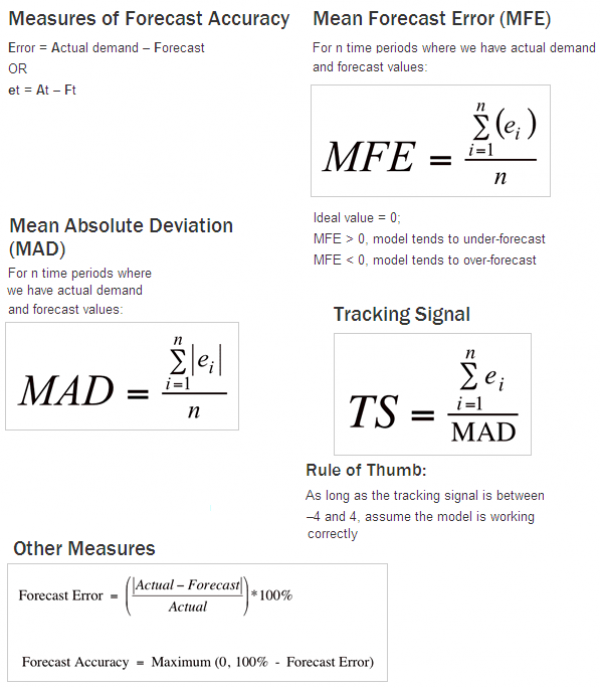

Forecast accuracy is the difference bet’n the actual sales recorded in a given period & that predicted by

the sales forecasting process. Forecast at the product level should be monitored during the monthly SOP meeting. The rate at which actual sales are booked against predicted sales is a measure of

forecast accuracy. Forecasts for specific products should be monitored by the master scheduler by

comparing the actual sales for a specific product to the predicted level of sales. Forecast accuracy should be monitored by developing acceptable levels of forecast error by product group &/or by specific product.

Items that have stable demand & high volume should have lower acceptable errors than those

with less stable demand & lower volume. A trend analysis of the variability in the forecast will help

determine the stability of the item being forecasted.

Forecast variability can be measured by determining the magnitude of the standard deviation or the

mean absolute deviation. These measures assume a normal distribution of sales about the mean. The

higher the magnitude of the std deviation the greater the spread of the normal distribution & the greater

the range of forecast variability.

The next issue in forecast performance measurement is the development of sample size. This measure

is based on analysis of the population being studied. Depending on the group & how the sample is

developed small nos. of observations can predict the behavior of larger groups of the population. This is

the theory behind customer service surveys, opinion polls, market analysis & statistical samplings.

Tracking signal is a way to determine when a forecasting technique for an item needs to be reviewed. A

tracking signal is activated when the running some of forecast errors when compared to the mean

absolute deviation of a distribution exceeds the no.4. Tracking signals are useful for determining the

turning points in a product life cycle as they indicate that the actual sales are no longer following the

historical trend.

Outliers are defined as data points that do not fit the overall pattern & trend in a population. It is important

to separate the true outliers from the data points that do have casual factors. A true outlier is either a

mistake in data entry or a one time event that will never be repeated. It’s important not to remove outliers

that are caused by factors that could potentially be repeated.

Demand filters are used as a means for controlling variation by providing a check that limits the amount

of variation from one period to the next.

Forecasting Monitoring: Forecasts should be monitored on a regular & ongoing basis. It is necessary

to establish the lower & upper control limits to the forecast accuracy. In some companies forecast is the

responsibility of mktg dept & in other companies it is the responsibility of operations dept. In general

terms the ownership of the forecasting process is best positioned in sales & mktg dept. A defined group

is assigned the responsibility of generating the forecast & that they are measured on the accuracy of the

forecast that they generate on the regular basis.