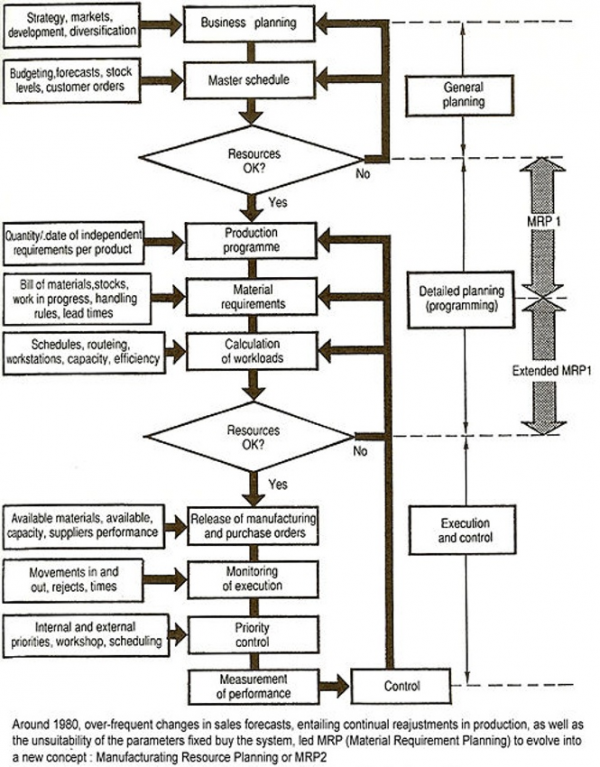

Manufacturing Resources Planning (MRP II)

MRP II stands for Manufacturing Resources Planning, a computer modelling technique for analysing and controlling complicated Manufacturing operations. When the manufacturing data has been collected (parts, assemblies, resources) the lead time and cost of every component can be predicted under any manufacturing conditions. As soon as an order is received the workload on the manufacturing organisation and the delivery time can be calculated. MRP II systems also keep track of customers, suppliers and accounting functions. Inventory can be purchased and assemblies made "Just in Time". The records kept by an MRP system highlight inadequacies such as overloaded production centres and delays by suppliers. The effect of new orders, changes in capacity, shortages, delays and a myriad of other disturbances are calculated and tracked with confidence.

The major effects that an MRP II system will have on a manufacturing operation will be:

- Reduced inventory.

- Accurately predicted delivery times.

- Accurate costing at every stage of the manufacturing process.

- Improved use of manufacturing facilities.

- Faster response to changing conditions.

- Control of every stage of production.

The main advantages of MRPII over MRP are

1. Feedback

MRP II includes feedback from the shop floor on how the work has progressed, to all levels of the schedule so that the next run can be updated on a regular basis. For this reason it is sometimes called 'Closed Loop MRP'.

2. Resource Scheduling

There is a scheduling capability within the heart of the system that concentrates on the resources, i.e. the plant and equipment required to convert the raw materials into finished goods. For this reason the initials `MRP' now mean Manufacturing Resources Planning. The advantages of this development are that detailed plans can be put to the shop floor and can be reported on by operation, which offers much tighter control over the plant. Moreover loading by resource means that capacity is taken into account. The difficulty is that capacity is only considered after the MRP schedule has been prepared. It may turn out that insufficient time was allowed within the MRP schedule for the individual operations to be completed.

3. Batching Rules

Batching rules can be incorporated, indeed they have to be if resource scheduling is to take place. Most software packages offer a variety of batching rules. Three of the more important are 'Lot for Lot', 'EBQ' and 'Part Period Cover'.

•'Lot for Lot' means batches that match the orders. Therefore if a company is planning to make 10 of Product A followed by 20 of Product B, then the batches throughout the process will match this requirement. If both A and B require two of a certain sub assembly then that will be made in quantities of 20 of A and 40 of B. It is the batching implicitly followed in basic MRP.

•'EBQ' stands for Economic Batch Quantity . The batch size is calculated by a formula that minimises the cost through balancing the set up cost against the cost of stock.

•'Part Period Cover' means making batches whose size cover a fixed period of demand. A policy of making a weeks requirement in one batch is an example.