Forecast Decissions

Leading Indicators:

There are several types of forecasts that are based on external indicators factors that determine the demand performance of a related item. E.g. the demand for new housing will have direct impact on the demand for the constriction materials, interior furnishings & appliance purchases. A causal factor is a factor that creates demand for a specific product.

A good example of the use of causal factors in forecasting is the development of a forecast for a crop pesticide based on causal factors. Published information defines the number of acres of a particular crop. That will be planned next season. The company then estimates the amount of corps that will be treated with pesticide. They then estimate their share of the market & determine the amount of pesticide normally used per acre.

New Product Introduction:

The challenge for a new product is to forecast demand for a product that has never been sold before. An example of the need for this kind of forecast is the area of ‘”provisioning” of aircraft spare parts. The question arises as how many spare parts to carry in each regional maintenance center to support the fleet in active service with a minimum of aircraft downtime. Before the regional jet had completed it’s flight testing, decisions had to be made about the initial & replenishment stocking levels for all spare & service parts for the entire aircraft fleet. Forecasts were made on the likely number of flight hours before various spare parts would need to be replaced.

A preventive maintenance schedule was developed based on predicted mean time between failure statistics that had been estimated by design engineering. Stocking levels were then established using safety stocks based on the potential error in the forecast. As soon as the aircraft entered active service, actual data were used to replace estimates & stocking levels were adjusted.

Some companies are introducing products that are in the same family as is a previous product, or replacement products & they can use historical analogy as a good indicator of future sales. The impact of introducing new product on the existing sales is important. When the customer is provided with choices he may buy the new model & sales. Historical analogy allows a company to minimise & manage the risk associated with the new product introduction.

Focus Forecasting:

Focus forecasting is “a system that allows the user to simulate the effectiveness of numerous forecasting techniques, enabling selection of the most effective one”. It was invented by Bernard Smith when he was working for Servistar in 1972. He was responsible for forecasting 20000 independent demand items, nuts, bolts, screws & fasteners. Focus forecasting is computer based simulation technique that compares the forecasts generated using any of 14 simple strategies.

The computer selects the best strategy to forecast this item at this moment in time. It does this through a process of simulation. The computer goes back through 3 periods at a time & pretends they did not happen & then projects the 3 periods using each of the simple strategies. Whichever strategy gives best fit to the actual results becomes the strategy selected to forecast this item at this point in time. The simulation can result in different strategies being applied to an item every period.

Following are the assumptions of focus forecasting:

a) The most recent past is the best indicator of the future.

b) One forecasting model is better than others.

c) All forecasting models will be compared for all items forecasted.

d) Recent history will be forecasted for each item with each model.

e) The model which achieves the closest fit to actual product sales will be selected.

f) This model will be used to forecast this item this time.

Focus forecasting still used in Servistar, which forecasts 2,50,000 SKUs every month.

Data Issues for forecasting:

The accuracy of the forecast depends upon the following factors which are involved in data collection:

a) Availability of data: It is the access to historical information concerning the level of sales activity for a certain item. It is important to preserve the sales history when new systems are implemented.

b) Consistency of data: the data collected should be comparable from period to period. It is critical that the data are captured in the same terms. E.g. the item nos. should be the same over the entire period from which the sales information is being collected.

c) Amount of history: A product that is subject to seasonal demand at least to seasons of demand are required to establish the amount of seasonal activity.

d) Forecast frequency: It is the periodic interval bet’n the successive generation of the forecast. Mostly it is a month.

e) Cost & Time Issues: It refers to the cost associated with the generation of the forecast. There is an inherent cost associated with the acquisition, storage & processing of forecast information. This cost must be compared with the value of the forecast. There is also a time factor associated with a larger database; it takes more processing time to get results. The forecasting system needs to perform within prespecified cost & time standards.

f) Recording true demand: it is actual demand that is recorded for a product or service as opposed to the dates on which the company can support the customer’s request. True demand occurs at the level of the ultimate customer-the consumer or end user of the product or service.

g) Order date vs. ship date: When there is a significant lead time from requirement to delivery this information becomes very critical. The organization needs to develop 2 forecasts one at the level of order input received (a bookings forecast) & the other at the level of anticipated shipment (shipment forecast). This information also relates to the quantity ordered vs. the quantity shipped.

h) Product Unit vs. Financial Units: Sales & operations do not speak the same language.

i) Level of aggregation: It refers to the use of different forecasts & data at different levels within the organization. The level of overall business activity is expressed in the business plan, groups of products are expressed in the SOP & detailed schedules are expressed as specific units.

j) Custom Partnering: It improves communications thereby increasing accuracy of forecast. When the customers & the suppliers are partners the information is shared.

Planning Horizons & Time Periods:

a) Calendar: Mostly the future sales are forecasted by a month. If the sales forecasts by calendar month & operation forecasts by the number manufacturing days in a given month or quarter. In view of the possible variations, the need to establish an agreed upon company calendar for consistency & communication purpose is apparent.

b) Time periods & planning intervals: Common alternatives are days, weeks, months, quarters or years. The planning cycle refers to the frequency of revision to the plans are developed. Business plan is developed on an annual basis, a SOP on a monthly basis & a master production schedule on a

weekly or daily basis.

c) Planning Horizons: It is the length of time into the future for which the forecast will be generated. The planning horizon is equal to the length of the period multiplied by the number of periods. As a general rule the further into the future that the forecast is made, the less accurate the forecast will be. The forecast should cover a sufficient time for the specified planning purpose.

Data Preparation & collection:

The accuracy of source data is fundamental to the generation of sales forecasts. Collection & recording of the data is the most important aspect. The data should be collected in the same term as the forecast requires. If the forecast is expressed in weekly intervals then the data should be collected in weekly intervals.

It is important to record customer requested quantities not merely shipments since shipments are constrained by product or resource availability. Shipments may not reflect the true level of sales that were available to the company. The shipments are the measure of supply not demand.

Additionally the sales numbers do not include lost sales-sales that would have been realized if the product or service had been available at the time of customer need. It is important to estimate the level of lost sales to create a true forecast of potential sales that can be generated.

It is also important to track the original customer requested date vs. promised date. In a service organization lost sales may not be recorded. The customer can cancel the order or look for the alternative if he is dissatisfied with the service.

Forecast can be generated at many levels but will be more accurate at higher levels than at lower levels. Forecasts can be aggregated up the pyramid from the detail level to the aggregate level.

Dealing with Outliers:

“A data point that differs significantly from other data for a similar phenomenon. For example, if the average sales for a product were 10 units per month, and one month the product had sales of 500 units, this sales point might be considered an outlier”. Some forecasting system permits users to remove outliers from the data. In some cases the outliers may be a singular anomaly (a one time event) unlikely to be repeated at any time in the future. Regardless of whether or not this information is used for forecasting or sales projections including the outlier will distort the demand. The outlier may be caused by the events that have a probability of recurrence. It is always easier to remove the problem outlier than to

adjust the forecast model that may need to be changed.

Decomposition of data:

Decomposition is “a method of forecasting where time series data are separated into up to three components: trend, seasonal, and cyclical; where trend includes the general horizontal upward or downward movement over time; seasonal includes a recurring demand pattern such as day of the week, weekly, monthly, or quarterly; and cyclical includes any repeating, non seasonal pattern. A fourth component is random, that is, data with no pattern. The new forecast is made by projecting the patterns individually determined and then combining them”. Steps in decomposition are:

1. Purify the data,

2. Adjust the data,

3. Take out the baseline & components,

4. Identify demand components,

5. Measure the random error,

6. Project the series,

7. Recompose.

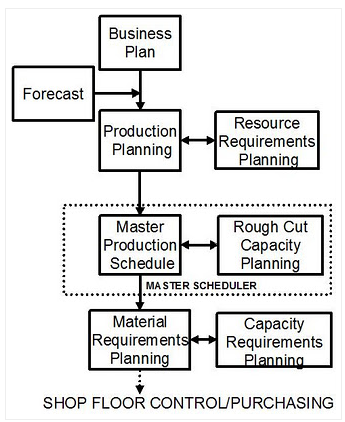

A business plan is usually stated in terms of dollars and grouped by product family. The business plan is then translated into synchronized tactical functional plans through the production planning process (or the sales and operations planning process). Although frequently stated in different terms (dollars versus units), these tactical plans should agree with each other and with the business plan. It’s a document consisting of the business details (organization, strategy, and financing tactics) prepared by an entrepreneur to plan for a new business.

A business plan is usually stated in terms of dollars and grouped by product family. The business plan is then translated into synchronized tactical functional plans through the production planning process (or the sales and operations planning process). Although frequently stated in different terms (dollars versus units), these tactical plans should agree with each other and with the business plan. It’s a document consisting of the business details (organization, strategy, and financing tactics) prepared by an entrepreneur to plan for a new business.

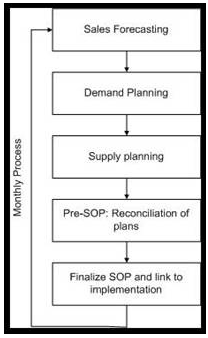

A Sales and Operations Planning process normally includes a series of meetings, finishing with a board level meeting at which, key long term decisions are taken, and the current progress against the Business Plan is reviewed. The review has to cover at least 15 months.

A Sales and Operations Planning process normally includes a series of meetings, finishing with a board level meeting at which, key long term decisions are taken, and the current progress against the Business Plan is reviewed. The review has to cover at least 15 months.