Production Strategies

There are 3 basic strategies that can be used in developing a production plan: subcontracting, a level strategy and a chase strategy. Firms may choose to utilize one of the pure strategies in isolation, or they may opt for a strategy that combines the three.

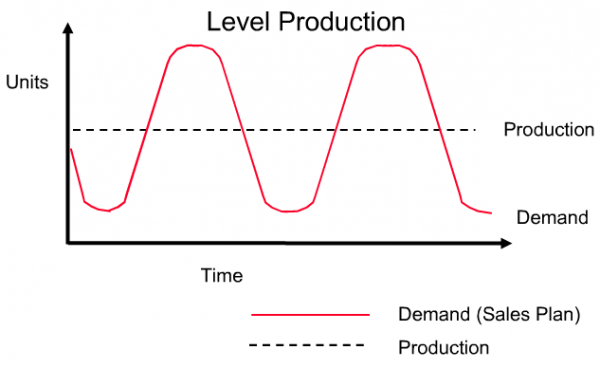

LEVEL STRATEGY

A level strategy seeks to produce an aggregate plan that maintains a steady production rate and/or a steady employment level. In order to satisfy changes in customer demand, the firm must raise or lower inventory levels in anticipation of increased or decreased levels of forecast demand. The firm maintains a level workforce and a steady rate of output when demand is somewhat low. This allows the firm to establish higher inventory levels than are currently needed. As demand increases, the firm is able to continue a steady production rate/steady employment level, while allowing the inventory surplus to absorb the increased demand.

A second alternative would be to use a backlog or backorder. A backorder is simply a promise to deliver the product at a later date when it is more readily available, usually when capacity begins to catch up with diminishing demand. In essence, the backorder is a device for moving demand from one period to another, preferably one in which demand is lower, thereby smoothing demand requirements over time.

A level strategy allows a firm to maintain a constant level of output and still meet demand. This is desirable from an employee relations standpoint. Negative results of the level strategy would include the cost of excess inventory, subcontracting or overtime costs, and backorder costs, which typically are the cost of expediting orders and the loss of customer goodwill.

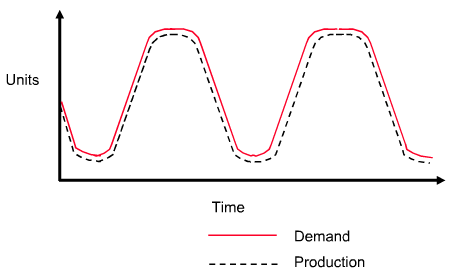

CHASE STRATEGY

A chase strategy implies matching demand and capacity period by period. This could result in a considerable amount of hiring, firing or laying off of employees; insecure and unhappy employees; increased inventory carrying costs; problems with labor unions; and erratic utilization of plant and equipment. It also implies a great deal of flexibility on the firm's part. The major advantage of a chase strategy is that it allows inventory to be held to the lowest level possible, and for some firms this is a considerable savings. Most firms embracing the just-in-time production concept utilize a chase strategy approach to aggregate planning.

SUBCONTRACT STRATEGY

As a pure strategy, subcontracting means always producing at the level of minimum demand and meeting any additional demand through subcontracting. The major advantage of this strategy is cost. Costs associated with excess capacity are avoided and there are no costs associated with changing production levels. The main disadvantage is

that the cost of purchasing (item cost, purchasing, transportation and inspection costs) may be greater than if the items were made in the plant.

There are several other factors that may be considered. Firms may manufacture to keep confidential processes within the company, to maintain quality levels and a workforce.

HYBRID STRATEGY

The three strategies discussed so far are pure strategies. There are many possible hybrid or combined strategies a company may use. Each will have its own set of cost characteristics. Production manager is responsible for finding the combination of strategies that minimize the sum of all costs involved, providing the level of service required and meeting

the objectives of the financial and marketing plans.