Time Fences

“A policy or guideline established to note where various restrictions or changes in operating procedures take place. For example, changes to the master production schedule can be accomplished easily beyond the cumulative lead time, while changes inside the cumulative lead

time become increasingly more difficult to a point where changes should be resisted. Time fences can be used to define these points”.

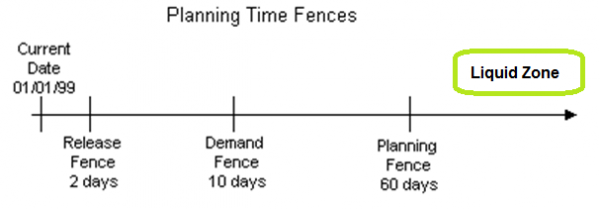

Time Fence is an artificial time boundary used to separate periods or groups of periods for planning purposes

At each of the stages of a bill of material, the company commits itself to more cost and fewer alternatives. Therefore the cost of making a change increases and the company’ s flexibility decreases as production gets closer to the delivery time. Bur changes to MPS is ineviatble & might occur for below reasons:

- Customers cancel or change orders;

- Suppliers have problems and miss delivery dates;

- Machines break down or new machines are added, changing capacity;

- Processes create more scrap than expected.

A company wants to minimize the cost of manufacture and also be flexible enough to adapt to changing needs. Changes to production schedules can result in the following:

- Cost increases due to re-routing, rescheduling, extra setups, expediting and buildup of work-in-process inventory;

- Decreased customer service. A change in quantity of delivery can disrupt the schedule of other orders;

- Loss of credibility for the MPS and the planning process.

Changes that are far off on the planning horizon can be made with little or no cost or disruption to manufacturing. To help in the decision-making process, companies establish zones divided by time fences. The zones and time fences are

Release Time Fence :

Release time fence used to allow automatic release of orders falling within this planning horizon. For example, a planner may want to automatically create released orders for certain items when the requirement falls within 1 or 2 days of the current date.

Demand Time Fence (Frozen zone):

It is “1) That point in time inside of which the forecast is no longer included in total demand and projected available inventory calculations; inside this point, only customer orders are considered. Beyond this point, total demand is a combination of actual orders and forecasts, depending on the forecast consumption technique chosen.

2) In some contexts, the demand time fence may correspond to that point in the future inside which changes to the master

schedule must be approved by an authority higher than the master scheduler. Note, however, that customer orders may still be promised inside the demand time fence without higher authority approval if there are quantities available-to-promise (ATP). Beyond the demand time

fence, the master scheduler may change the MPS within the limits of established rescheduling rules, without the approval of higher authority”.

Capacity and material are committed to specific orders. Since changes would result in excessive costs, reduced manufacturing efficiency and poor customer service, senior management’ s approval is usually required to make changes. The extend of the frozen zone is defined by the demand time fence. Within the demand time fence, demand is usually based on customer orders, not forecast.

Planning time fence(Slushy zone):

Capacity and material are committed to less extend. This is an area for tradeoffs that must be negotiated between marketing and manufacturing. Materials have been ordered and capacity established; these are difficult to change. However, changes in priorities are easier to change. The extent of the slushy zone is defined by the planning time fence. Within this time fence the computer will not reschedule MPS orders.Changes inside the planning time fence must be made manually by the master scheduler.

Outside the planning time fence, customer orders may be booked and changes to the master schedule can be made within the constraints of the production plan.

Liquid zone:

Any change can be made to the MPS as long as it is within the limits set by the PP. Changes are routine and are often made by the computer program.

Oracle EBS

Demand Time Fence Control

The demand time fence is bordered by the current date and a date within which the planning process does not consider forecast demand when calculating actual demand. Within the demand time fence, Oracle Master Scheduling/MRP and Supply Chain Planning only considers actual demand. Outside the demand time fence, the planning process considers forecast demand. You can specify whether to use demand time fence control when loading a master schedule and launching the planning process.

Planning Time Fence Control

The planning time fence is bordered by the current date and a date within which the planning process does not alter the current material plan or master schedule. You can specify whether to use planning time fence control when launching the planning process.

For discrete items within the planning fence, the planning process does not reschedule in (create earlier) order due dates or create new planned orders for the item to satisfy net demand requirements. However, the planning process can reschedule out or cancel an order when it determines that such orders create excess supply. For discrete items outside the planning time fence, the planning process can generate suggestions to create, change, and reduce entries on the master schedule or the material requirements plan.

For repetitive items, Oracle Master Scheduling/MRP and Supply Chain Planning restricts the planning process to suggest rates of production within the planning time fence that differ from the current aggregate repetitive schedule by no more than the acceptable rate increase and acceptable rate decrease you defined for the item. If either the acceptable rate increase or decrease value is undefined, the planning process is not restricted from increasing or decreasing the repetitive schedule respectively.

Release Time Fence Control

The release time fence is bordered by the current date and a date within which the planning process automatically releases planned orders to Oracle Work in Process as discrete jobs or to Oracle Purchasing as purchase requisitions. You can specify whether to use release time fence control when defining your plan name.

Time Fences and Firm Orders

A firm order is an order that is frozen in quantity and time (unavailable for rescheduling). Oracle Master Scheduling/MRP and Supply Chain Planning automatically creates a planning time fence for the firm order if the firm order exists after the planning time fence date. There are two methods you can use to firm an order that creates a time fence: you can firm a planned order or firm a discrete job in the Planner Workbench, or you can firm a discrete job or purchase order within Oracle Work in Process and Oracle Purchasing directly.

Oracle Master Scheduling/MRP and Supply Chain Planning creates a time fence for a firm order because it implies that resources committed to meeting the firm order would be unavailable for orders scheduled earlier.

You can use the profile option MRP:Firm Planned Order Time Fence to indicate whether to form natural time fences for your MRP firm planned orders when launching the planning process.