Planning for Execution

PAC is responsible for planning and preparing order’ s release to the shop floor. The order should be reviewed to be sure that the necessary tooling, material and capacity are available. Tooling is not generally considered in MRP program, so at this

stage, material availability must be checked. Checking capacity availability is a twostep process. First, the order must be scheduled to see when the capacity is needed, and second, the load on work centers must be checked in that period.

Scheduling

The objectives of scheduling is to meet delivery dates and to make the best use of manufacturing resources. It involves establishing start and finish dates for each operation required to complete an item. To develop a reliable schedule, the planner must have information on routing, required and available capacity, competing jobs and manufacturing lead times at each work center involved.

Job shop scheduling (or Job-shop problem) is an optimization problem in computer science in which ideal jobs are assigned to resources at particular times. The most basic version is as follows:

We are given n jobs J1, J2, ..., Jn of varying sizes, which need to be scheduled on m identical machines, while trying to minimize the makespan. The makespan is the total length of the schedule (that is, when all the jobs have finished processing).

There are many techniques to schedule shop orders through a plant, but all of them require an understanding of forward and backward scheduling as well as finite and infinite loading.

Forward Scheduling : APICS Defines forward scheduling as a scheduling technique where the scheduler proceeds from a known start date and computes the completion date for an order, usually proceeding from the first operation to the last. Dates generated by

this technique are generally the earliest start dates for the operations.

Forward Scheduling is used to develop promise dates for customers

May focus on critical operations, identifying when they would next be available, then scheduling through subsequent operations

Works poorly for complex product structures

Assembly component lead times differ, but must be scheduled to be available concurrently to start assembly.

Many paths through the structure need to be calculated, adjusted to the timing of the longest path.

Can be used to supplement backward scheduling to solve problems, respond to customer needs

A job is behind schedule – will it be possible to catch up? Will the order have to be rescheduled?

A major customer needs a spare part as soon as possible – how quickly can we produce it?

Backward scheduling. The last operation on the routing is scheduled first and is scheduled for completion at the due date. Previous operations are scheduled back from the last operation. Work-in-process inventory is reduced, but because there is little slack time in the system, customer service may suffer. Backward scheduling is used to determine when an order must be started.

In backward scheduling MRP establishes the completion dates. Independent demand quantities and timings are based on the MPS.

Order completion dates and release dates are determined for each part in the product structure, using the planned lead times for each part number MRP plans order due dates and release dates and keeps them up-to-date by adjusting for changes in schedules, lead times, product structure.

Typically work centers have several jobs waiting in line to be done. Which should go first? Order due dates alone do not provide an answer. Priority should be determined based on working a backward schedule and comparing the release dates against customer required schedule.

Infinite loading. It does not consider the existence of other shop orders competing for capacity at these work centers. It assumes infinite capacity will be available. Notice the over and under load.

Finite loading assumes there is a defined limit to available capacity at any workstation. If there is not enough capacity available at a workstation because of other shop orders, the order has to be scheduled in a different period time. The load is smoothed so there is no overload condition.

Reducing MLT

Operation overlapping

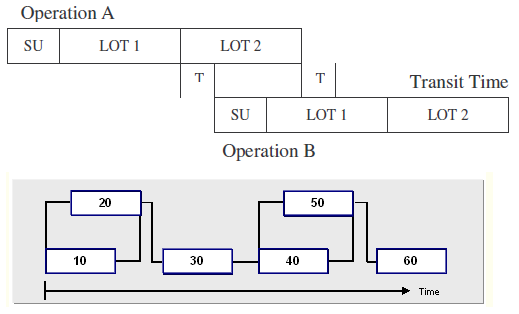

In operation overlapping, the next operation is allowed to begin before the entire lot is completed on the previous operation. This reduces the total manufacturing lead times. An order is divided into at least 2 lots. When the first lot is completed on operation A, it is transferred to operation B.

In figure, it is assumed operation B cannot be set up until the first lot is received, but this is not always the case. If the lots are sized properly, there will be no idle time at operation B. The manufacturing lead time is reduced by the overlap time

and the elimination of queue time.

Operation overlapping is a method of expediting an order, but there are some cost involved. First, move costs are increased, especially if the overlapped operations are not close together. Second, it may increase the queue and lead time for other orders. Third, it does not increase capacity but potentially reduces it if the second operation is idle waiting for parts from the first operation.

The problem is deciding the size of the sub-lot. If the run time per piece on operation B is shorter than on A, the first batch must be large enough to avoid idle time on operation B.

Operation Splitting

When a number of components are to be processed by a machine operation, the leadtime required to do so may be halved if 50% of the components are able to be processed by a second alternative machine. (Naturally, the operation splitting between the two machines requires that a second operator should be available, and a second set of tools.) It is noted that since there are now two works orders, each for half the original amount, planned quantities in the planning system must be corrected and an additional set of shop floor paperwork generated. It is also noted that a second set-up is required, casting doubt over the economics of splitting an operation between three machines.

Operation splitting is practical when:

- setup time is low compared to run time,

- a suitable work center is idle,

- it is possible for an operator to run more than one machine at a time.

The last condition often exists when a machine cycles through its operation automatically, leaving the operator time to set up a other machine. The time to unload and load must be shorter than the run time per piece.