Selecting Supplier/Approved Supplier List

Once the decision is made about what to buy, the selection of the right supplier is the next most important purchasing decision. A good supplier is one that has technology to make the product to the required quality, has the capacity to make the quantity needed and can run the business well enough to make a profit and still sell a product competitively.

Multinational companies usually maintain a central procurement department. These departments maintain a list of approved suppliers for all the purchased item. Central procurement department activates includes - creating request for quotation, quotation analysis, selecting a vendor, price negotiations, long term contracts and agreement etc.

There are 4 types of sourcing: sole, single, dual & multiple.

- Sole sourcing implies that only one supplier is available because of patents, technical specifications, raw material, location and so forth.

- Single sourcing is a planned decision by the organization to select one supplier for an item when several sources are possible. It is intended to produce a long-term partnership.

- Dual sourcing implies that only two vendors for the inventory items.

- Multiple sourcing is the use of more than one supplier for an item. The potential advantages are that competition will result in lower price and better service and that there will be a continuity of supply. In practice there is a tendency toward a adversarial relationship between supplier and customer.

Factors in selecting suppliers

Function, quantity, service and price are what the supplier is expected to provide and are the basis for selection and evaluation. Considering this there are several factors in selecting a supplier.

Technical ability. The buyer will depend upon the supplier to provide product improvements that will enhance or reduce the cost of the buyer’s products. Sometimes the supplier can suggest changes in product specification that will improve the product and reduce the cost.

Manufacturing capability. Manufacturing must be able to meet the specifications for the product consistently while producing as few defect as possible. The supplier must have a good quality control program, competent and capable

manufacturing personnel and good manufacturing planning and control system to ensure timely delivery.

Reliability. If the relationship is to continue, there must be an atmosphere of mutual trust and assurance that the supplier is financially strong enough to stay in business.

After-sales service. If the product is of a technical nature or likely to need replacement parts or technical support, the supplier must have a good after-sales service. This should include a good service organization and inventory of service

parts.

Supplier location. Sometimes it is desirable that the supplier be located near the buyer, or at least maintain an inventory locally. A close location helps shorten delivery times and means emergency shortages can be delivered quickly.

Other considerations. Sometimes other factors such as credit terms, reciprocal business and willingness of the supplier to hold inventory for the buyer should be considered.

Price. The supplier should be able to provide competitive prices. In a modern business environment, the type of relationship between the supplier and the buyer is crucial to both. The supplier can rely on future business and the buyer will have an assured supply of quality product, technical support and product improvement. Both parties understand the problems of the other and can work together to solve problems to their mutual advantage.

Identifying suppliers

One major responsibility of the purchasing department is to continue to research all available source of supply. Some aids for identifying sources of supply follow:

- Salespersons of the supplier company,

- Catalogues,

- Trade magazines,

- Trade directories,

- Information obtained by the salespeople of the buyer firm.

Final Selection of Supplier

Some factors in evaluating potential suppliers arc quantitative, and a dollar value can he put on them. Price is the obvious example. Other factors are qualitative and demand some judgment to determine them. These are usually set out in a descriptive fashion. The supplier’s technical competence might be an example.

The challenge is finding some method of combining these two major factors that will enable a buyer to pick the best supplier. One method is the ranking method, described next.

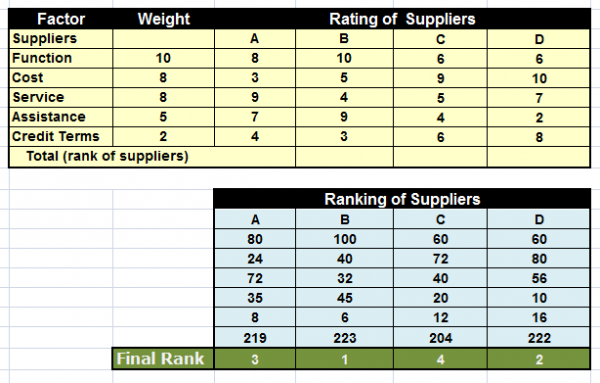

1. Select those factors that must be considered in evaluating potential suppliers.

2. Assign a weight to each factor. This weight determines the importance of the factor in relation to the other factors. Usually a scale of one to ten is used. If one factor is assigned a weight of five and another factor a weight of ten, the second factor is considered twice as important as the first.

3. Rate the suppliers for each factor. This rating is not associated with the weight. Rather, suppliers are rated on their ability to meet the requirements of each factor. Again, usually a scale of one to ten is used.

4. Rank the suppliers. For each supplier, the weight of each factor is multiplied by the supplier rating for that factor.

For example, if a factor had a weight of 8 and a supplier was rated 3 for that factor, the ranking value for that factor would he 24. The supplier rankings are then added to produce a total ranking. The suppliers can then be listed by total ranking and the supplier with the highest ranking chosen.

The given figure shows an example of this method of selecting suppliers. Theoretically, supplier B, with the biggest total of 223, will be selected.

The ranking method is an attempt to quantify those things that are not quantified by nature. It attempts to put figures on subjective judgment. It is not a perfect method. but it forces the buying company to consider the relative importance of the various factors.