Sales & Operations Plan

APICS defines S&OP as the "function of setting the overall level of manufacturing output (production plan) and other activities to best satisfy the current planned levels of sales (sales plan and/or forecasts), while meeting general business objectives of profitability, productivity, competitive customer lead times, etc., as expressed in the overall business plan. One of its primary purposes is to establish production rates that will achieve management’s objective of maintaining, raising, or lowering inventories or backlogs, while usually attempting to keep the workforce relatively stable. It must extend through a planning horizon sufficient to plan the labor, equipment, facilities, material, and finances required to accomplish the production plan. As this plan affects many company functions, it is normally prepared with information from marketing, manufacturing, engineering, finance, materials, etc."

APICS defines S&OP as the "function of setting the overall level of manufacturing output (production plan) and other activities to best satisfy the current planned levels of sales (sales plan and/or forecasts), while meeting general business objectives of profitability, productivity, competitive customer lead times, etc., as expressed in the overall business plan. One of its primary purposes is to establish production rates that will achieve management’s objective of maintaining, raising, or lowering inventories or backlogs, while usually attempting to keep the workforce relatively stable. It must extend through a planning horizon sufficient to plan the labor, equipment, facilities, material, and finances required to accomplish the production plan. As this plan affects many company functions, it is normally prepared with information from marketing, manufacturing, engineering, finance, materials, etc."

Key points of sales & operation planning are

1. SOP is a process for continually revising the SBP and coordinating plans of the various departments.

2. SOP is a cross-functional business plan that involves sales and marketing, product development, operations and senior management. While operations represent supply, marketing represents demand.

3. The SOP is the forum in which the production plan is developed.

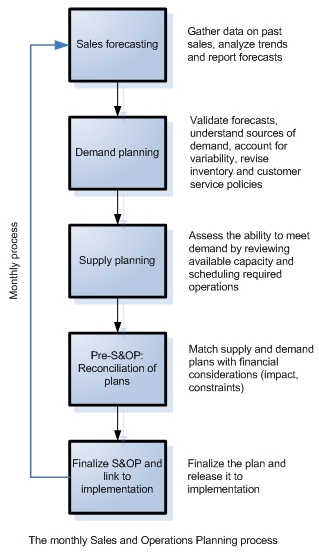

4. SOP is a dynamic process, updated on a regular basis, usually monthly. The process starts with the sales and marketing departments. The updated marketing is then communicate to manufacturing, engineering and finance which adjust their plans. If these departments find they cannot accommodate the new marketing plan, then the marketing plan must be adjusted.

There are two approaches that are used in sales and operations planning; top-down planning and bottom-up planning.

Top-Down Planning

Top-down planning is the simplest approach to sales and operations planning. In this approach, there is a single sales forecast that drives the planning process. The forecast is derived from a combination of products and services that require similar resources, for example, a number of manufactured finished products. Using top-down planning, the management can create tactical plans based on the overall forecast and divide the resources across the finished foods in the plan. Bottom-Up Planning

This approach is used by companies that do not have a stable manufacturing schedule and the number and type of finished goods can change from month to month. In this scenario the sales forecast is not helpful for resource planning. The management need to calculate the resources for each of the products and then amalgamate the resources to get an overall picture of resource requirements.